My Garage

My Account

Cart

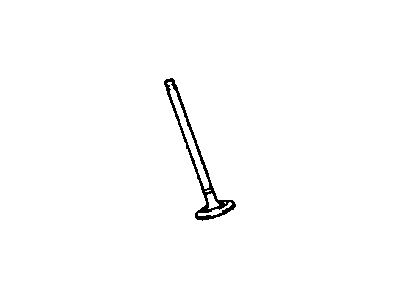

Genuine Dodge Colt Exhaust Valve

Exhaust Muffler Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Exhaust Valves found

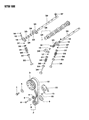

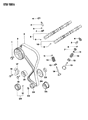

Dodge Colt Exhaust Valve

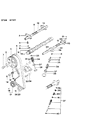

The Exhaust Valve is designed to be an important component in the internal combustion engine for the Dodge Colt vehicles and its function is to act as an exhaust outlet for the burned gases in the engine cylinders. This function is critical for a superior engine performance, as any harm to the Exhaust Valve may result into less power, occasional ignition, rough running, and lowered fuel efficacy. The Dodge Colt has been fitted with many styles of Exhaust Valves over the years with each being intended to optimally control the flow of exhaust gases. While specific types are not detailed, the primary mechanism remains consistent: helping in the process of expulsion of exhaust gases so as to enable the operation of the engine. Information concerning the Exhaust Valve is therefore crucial for ensured optimal performance and durability of the Dodge Colt vehicles.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Colt Exhaust Valve at great affordable prices. Moreover, all genuine Dodge Colt Exhaust Valve come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Colt Exhaust Valve Parts Questions & Experts Answers

- Q: How to adjust valve clearance on Dodge Colt?A:For the setting of the cold clearances after a major overhaul, the actual starting clearance would require the clearing of the half-hot and the normal service checks when the motor is at normal operating temperature. Initial steps involves the of the air cleaner, pulling out the breather hose and unbolting the rocker cover. There are two ways that are used to check and, if necessary, adjust the valve clearances. In the first method, use a ring spanner on the center bolt of the Crankshaft pulley to turn the crankshaft until the rocker arm for No 1 cylinder 'just rocks', this means the inlet valve is opening, and the exhaust valve is closing. Position a new set of feeler blades between the face of the No 4 rocker arm screws and the end of the valve stems in such a manner that the feeler blade will only slide in a stiff manner. If not, also unlock the adjuster screw locknut, adjust it until it is right then lock the locknut and do not rotate the adjuster screw. Proceed by rotating the crankshaft and inspects and adjusts the rest of the valves one by one. In the second method, with the assistance of a ring spanner on the crankshaft pulley center bolt, turn the engine until the No 1 piston is at the TDC of the compression stroke more so when both valves of the cylinder are closed. Turn the crankshaft one full turn anticlockwise and if the valves are marked, check the actual clearance on the valve stems. Last, make sure all locknuts are torqued, reinstall the rocker cover and the air cleaner and unset the ring spanner of the crankshaft pulley bolt.