My Garage

My Account

Cart

Genuine Dodge Magnum Rocker Arm

Engine Rocker Arm- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Rocker Arms found

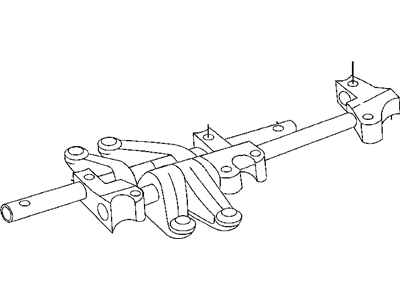

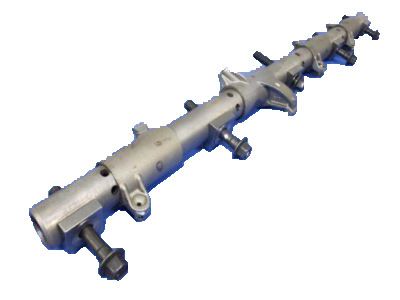

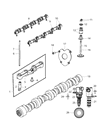

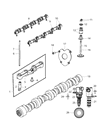

Dodge Magnum Engine Intake Rocker Arm

Part Number: 53021552AA$151.88 MSRP: $227.00You Save: $75.12 (34%)

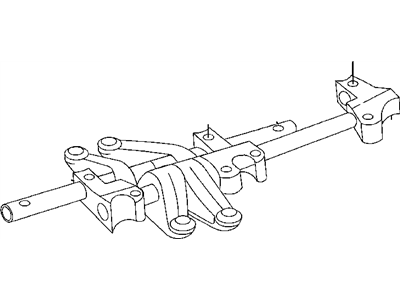

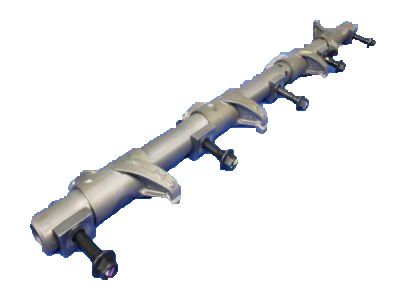

Dodge Magnum Rocker Arm

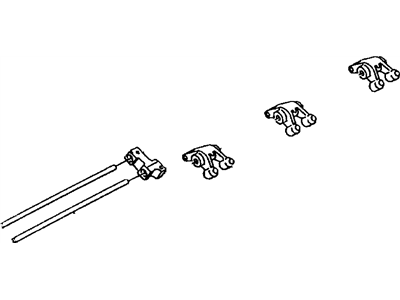

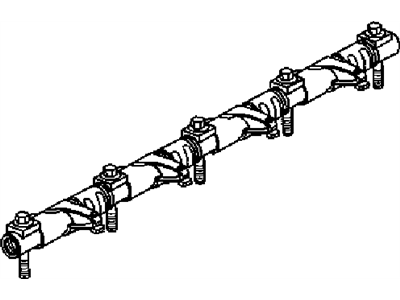

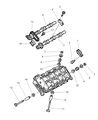

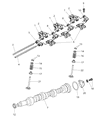

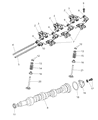

The Rocker Arm in Dodge Magnum vehicles plays a significant function in engines valve train mechanism as it ensures the conversion of movement of the pushrod to the intake and exhaust values. Usually made from stamped steel, aluminum or some high strength alloy, the Rocker Arm is designed to translate the oscillation or back-and-forth movement of the pushrod vertically into the kind of downward movement required to dilate the valves. Silicon alloy is used in high-RPM applications due to its low weight whereas cast iron or forged carbon steel is used in diesel engine for high durability. Some Dodge Magnum cars may have roller rockers that deploy needle bearing in the enhancement of the efficiency of the car as opposed to traditional metal on metal rolling. The rocker ratio which is standard in modern engines is between 1.5:1 and 1.8:1 enables increased camshaft lift and thus increases its efficiency. This is particularly applicable in high RPM engines of Dodge Magnum that include upgraded fulcrum bearings to fix stress/weight problems regarding the Rocker Arm and thereby increasing its performance and durability.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Magnum Rocker Arm at great affordable prices. Moreover, all genuine Dodge Magnum Rocker Arm come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Magnum Rocker Arm Parts Questions & Experts Answers

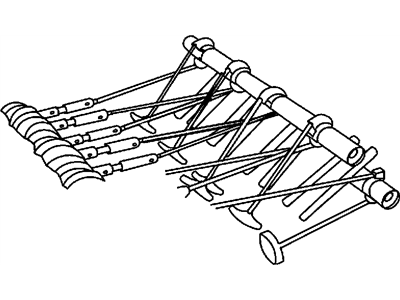

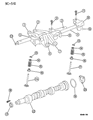

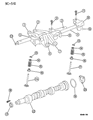

- Q: How do you remove Pushrod and Rocker Arm in V8 engine on Dodge Magnum?A:In order to take off the valve covers on the Cylinder Heads, loosen the rocker arm shaft bolts by first unbolting the middle ones to outer ones. Fully loosen the bolts and pull up rocker shaft assembly from off of the cylinder head. Keep track of rocker arm positions and store each set of rockers so that they can be reinstalled in their original positions. Remove push rods and store them in a way that prevents mixing them up at installation time. When examining the rocker arms, search for wear, cracks, and other types of damages particularly where it comes into contact with both pushrods as well as valve stems. Similarly, look at the rocker arm bores and shafts for any signs of stress cracks, galling or wear patterns that are not usual. Any worn out or damaged parts should be replaced with new ones including installing new shafts as well. Make sure there is an opening at each end hole part of all rocker arms' pushrods. Examine push rods for end cracks excessive wear; also check them by running across a plate glass to see if they are bent or rolled. To lubricate lower ends before replacing in lifter socket put clean engine oil or engine assembly lube on lower end of each pushrod; this will ensure that they seat properly in their original places when installed again.Apply some engine assembly lube to protect valve stem ends and upper portion of stem from damage during initial start-up process. At first lubricate most components present on top sides such as upper ends for push rods together with valve stem bottoms using either pure old engine oil or brand new motor assembly greases hence avoiding knocks while starting up your vehicle for instance Rocker arm has being fully oiled using either just refined old motor oil or absolutely unused motor grease with complete assemble back onto cylinder heads through which it is expected must have gone through full application treatment.Tighten center bolt first then followed by center right bolt, center left bolt, outer right bolt, and finally the outer left bolt for rocker arm shafts. Tighten bolts, making sure that as the tightening process is proceeding push rods are properly seat in rocker arms. If such conditions develop where rocker arm bolts start becoming tight before shaft has been completely seated or else push rods are binding; all rocker arm shafts must be removed followed by totally checking all components before taking next action. Lastly install valve covers and start the engine to listen for unusual sounds from valve train and observe oil leaks at valve cover gaskets.