My Garage

My Account

Cart

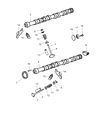

Genuine Dodge Neon Camshaft

Cam- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Camshafts found

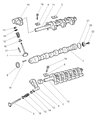

Dodge Neon Engine Exhaust Camshaft

Part Number: 4781679AB$219.41 MSRP: $457.00You Save: $237.59 (52%)

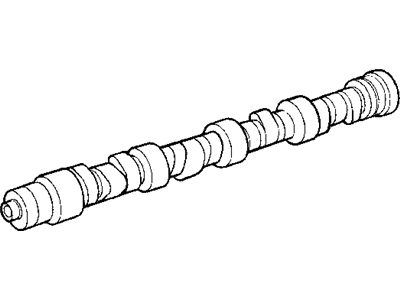

Dodge Neon Engine Exhaust Camshaft

Part Number: 4781679AA$219.41 MSRP: $457.00You Save: $237.59 (52%)

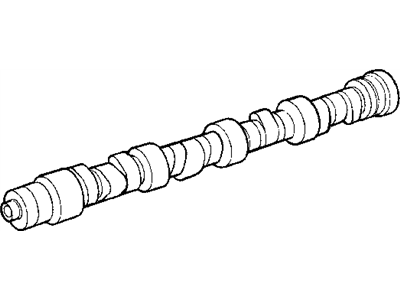

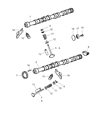

Dodge Neon Engine Intake Camshaft

Part Number: 4781681AB$302.17 MSRP: $457.00You Save: $154.83 (34%)

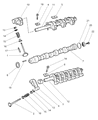

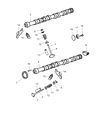

Dodge Neon Camshaft

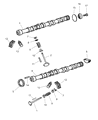

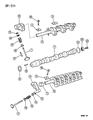

Camshaft in Dodge Neon automobiles is known to help in controlling the operations of the intake and exhaust valves which allow the admission of the air fuel blend into the engine chamber and the discharge of the exhaust gases as well. Dodge Neon camshaft is usually made from iron or steel and works through the eccentric lobes for the valves opening. Camshaft is synchronized with the crankshaft to ensure the right time of valve operating to gain the maximum efficiency. Camshaft configuration that has been used in Dodge Neon models include Over Head Valve (OHV), Single Over Head Cam (SOHC) and Double Over Head Cam (DOHC). All the types have an impact on the engines in unique ways, for example, DOHC provide individual camshafts for intake and exhaust, which yield better result at high engine speeds. The manufacture camshafts in the can also progress these characteristics with variants of lift, duration, and lobe separation according to the driving purpose.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Neon Camshaft at great affordable prices. Moreover, all genuine Dodge Neon Camshaft come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Neon Camshaft Parts Questions & Experts Answers

- Q: How can the camshaft be removed from the cylinder head on Dodge Neon?A:The camshaft, for instance, cannot be pulled out of its place when the Cylinder Head is still fitted in the car. Start by taking out all the cylinder heads and the Rocker Arm assemblies. Subsequent to this, remove the Camshaft position sensor and then gently pull the camshaft out through the rear opening of the cylinder head without harming the camshaft lobes or bearing journals in any way. Following removal, unscrew the/each seal from the camshaft(s) and wash them as well as the gasket surface. Camshaft lobes, and bearing journals, and seal contact surface should be checked for excessive wear or possible damage A camshaft end play that has increased or the camshaft bearing surface in the cylinder head has develop scoring or other unacceptable wear patterns. Check the camshaft bearing journal diameters with a micrometer while the inside diameter and face runout of the bearing surfaces in the cylinder head should be checked with an Artist PA-350 telescoping gauge. Deduct the journal measurement from the bearing measurement and establish the camshaft bearing oil clearance to compare this also. Clean the camshaft journals and apply clean engine oil to it and install the camshaft back in the cylinder head and the camshaft sensor. Mount a dial indicator to measure the camshaft end play and then check from the standard value of the camshaft. If any inspection reveals failure replace the camshaft, and in the case of worn out lobes also replace the rocker arms. Camshaft bearing surfaces in the head may be damaged or excessively worn or end play may be excessive so that cylinder head must be replaced. Before fitting, the journals of the camshaft should be cleaned before sliding some assembly lube or engine oil on the journals, lobes, and thrust areas and then slowly fitting the camshaft in the cylinder head. Place new camshaft oil seal and Camshaft Position sensor, cylinder head, rocker arm shaft assembly and Timing Belt with covers. Last but not the least step is to start the engine and look for oil leaks.