My Garage

My Account

Cart

Genuine Dodge Ramcharger Camshaft Bearing

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Camshaft Bearings found

Dodge Ramcharger Camshaft Bearing

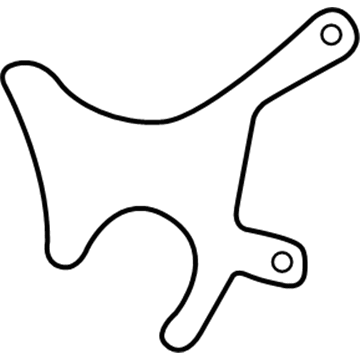

The Camshaft Bearing in Dodge Ramcharger cars is of great significance because it supports the camshaft for smooth rotation, which is important for regulating the engine's valve operation. Your vehicle requires this function for optimal engine operation. The bearings are generally cylindrical and precision machined to suit the engine block to allow proper lubrication from oil passages. Dodge Camshaft Bearing of different character may be applied such as the bi-metal bearing and the tri-metal bearing. Dodge bi-metal bearings are characterized with an aluminum alloy lining that sometimes is augmented by silicone to provide a higher degree of hardness and resistance to seizing. Tri-metal Dodge Ramcharger Camshaft Bearing on the other hand have a layer of copper alloy and a lead-tin-copper overlay giving them much better strength and fatigue resistance. The selection of the Ramcharger Camshaft Bearing type can have an impact on the engine performance and long life, depending on the particular application and performance factors.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Ramcharger Camshaft Bearing at great affordable prices. Moreover, all genuine Dodge Ramcharger Camshaft Bearing come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Ramcharger Camshaft Bearing Parts Questions & Experts Answers

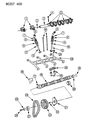

- Q: How to inspect Camshaft,Lash Adjuster and how to replace Camshaft Bearing on Dodge Ramcharger?A:The most definitive camshaft inspection technique is lobe lift measurement, and any of this must be done before the engine's disassembly. Initiated by including the removal of the rocker arm cover(s) then isolating the rocker arm shaft(s) from the Cylinder Head(s). Place the dial indicator with the stem touching the end of the exhaust valve pushrod; turn the Crankshaft slowly till the Lash Adjuster contacts the smallest part of the cam lobe, and this will be observed when the pushrod is lowest. Turn the crankshaft and align its number one cylinder with the zero mark of the dial indicator and then carry on rotating the crankshaft until the highest position of the pushrod is attained and record the reading then compare with the lobe lift. Do this for each of the remaining valve, but it is important to note that intake and exhaust valves may have different specification. If the measurements are not as specified a new camshaft should be installed in the engine of the vehicle. Once the camshaft has been pulled out, they should wiped clean with solvent and the surface of the bearing journals should be given a visual check for wear, pitting or signs of seizure; if found damaging both the camshaft and the bearings will need replacements. Camshaft mains Dia. should be measured inside with a micrometer to ascertain if the condition is worn or out of round to necessitate new bearings; bearings should be ascertained based on oil clearance. Examine the camshaft lobes for signs of heat checking, wear, chipped edges, pits, and signs of wear; provided the lobe lift figures are as laid down previously, the camshaft is reusable. Wash the Lash Adjusters individually and without getting them mixed up, and examine them for scuffing, scores, and nonuniform wear; if there is any Lash Adjuster that is worn concave or damaged, they should all be replaced. The Lash Adjuster foot should be slightly convex and if the Lash Adjuster walls are deformed the Lash Adjuster bores on the engine block should be checked. Replacing Lash Adjusters requires replacing the camshaft as well; it is permissible to place used Lash Adjusters back on just their original camshaft and in their original positions. Due to the fact that bearing of a camshaft is specific and sensitive, it is recommended to take the block to an automotive machine shop for intended purpose.