My Garage

My Account

Cart

Genuine Dodge Challenger Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

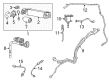

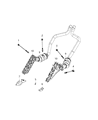

14 Oxygen Sensors found

Dodge Challenger Oxygen Sensor Left

Part Number: 68203458AA$91.29 MSRP: $138.00You Save: $46.71 (34%)

Dodge Challenger Oxygen Sensor

The Oxygen Sensor is an important attribute of the emission control in vehicles, used to maintain the Challenger engines high performance levels while at the same time ensuring clean emissions. This semiconductor reduces the amount of hydrogen in the merging exhaust gases and thus communicates to the ECU the amount of oxygen in the exhaust and enables the ECU to correct the A/F ratio. This dynamic adjustment is relevant as both rich and lean mixtures are harmful to the engine performance, as well as its life cycle. Oxygen sensors that have been incorporated in Dodge Challenger models comprise of zirconia and titania sensors. There are zirconia sensors which are manufactured in both narrow band and wide band, and they are particularly useful in the control of fuel mixtures. On the other hand, titania sensors work as they modify resistance as opposed to the generation of voltage. Anyhow, the Oxygen Sensor when malfunctioning leads to high emissions and fuel consumption thus needs replacement for the optimal performance of the vehicle.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Challenger Oxygen Sensor at great affordable prices. Moreover, all genuine Dodge Challenger Oxygen Sensor come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Challenger Oxygen Sensor Parts Questions & Experts Answers

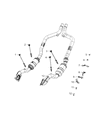

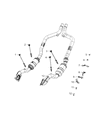

- Q: What is the role of oxygen sensors in emissions and fuel management on Dodge Challenger?A:The oxygen in the exhaust mix with such elements in the oxygen sensor to produce a voltage output of between 0.1v high oxygen, or lean mixture, and 0.9v low oxygen or rich mixture. The preconverter oxygen sensor, located upstream of the Catalytic Converter, provides a feed back signal to the PCM as to the amount of oxygen remaining in the exhaust, which the PCM constantly samples in order to adjust the fuel injector pulse width to maintain a stoichiometric air/fuel ratio of 14.7:1 for emissions, fuel economy and power. Unlike the upstream oxygen sensor after the catalytic converter, the so-called second oxygen sensor does not participate in the regulation of air/fuel ratio by the PCM but is used for evaluating the efficiency of the catalytic converter; it has a slower and oscillating voltage signal due to a lack of oxygen. Car manufacturers usually install four oxygen sensors; two of them are located upstream while the other two are downstream; upstream sensors are installed within the exhaust manifolds while downstream sensors are installed behind the catalytic converters. An oxygen sensor does not produce voltage below what seems to be its working temperature of around 600 degrees F; the PCM works in an open-loop fuel control mode relying on data received from other sensors during this time. Electric connections, supply of air, working temperature and unleaded fuel are vital in the good working of this oxygen sensor. The PCM can detect different types of oxygen sensor problems and set DTCs to signal specific problems, and go to open-loop fuel control when a DTC is present. For replacement, it is recommended to make the engine start for several turns in order to ease the process of the oxygen sensor's removal because of the constant contraction of the exhaust pipe. Upstream sensors are reached from the underside of the vehicle and downstream sensors are situated after the catalytic converters. When fitting a new sensor use a clean rag to clean the threads, if reusing the old sensor apply anti-seize compound, however new anti-seize compound pre-coated on new sensors. Turning off the negative terminal of battery for few minutes readjusts the PCM to the new sensor, but it will in the mean time have an impact on the engine performance since the PCM is now in the learning mode of different MPa.

Related Dodge Challenger Parts

Browse by Year

2023 Oxygen Sensor 2022 Oxygen Sensor 2021 Oxygen Sensor 2020 Oxygen Sensor 2019 Oxygen Sensor 2018 Oxygen Sensor 2017 Oxygen Sensor 2016 Oxygen Sensor 2015 Oxygen Sensor 2014 Oxygen Sensor 2013 Oxygen Sensor 2012 Oxygen Sensor 2011 Oxygen Sensor 2010 Oxygen Sensor 2009 Oxygen Sensor 2008 Oxygen Sensor