My Garage

My Account

Cart

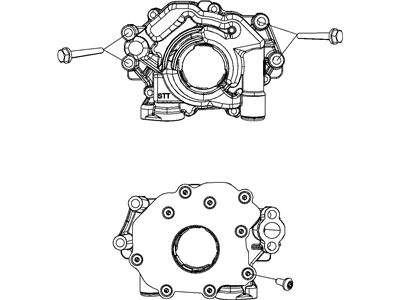

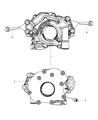

Genuine Dodge Durango Oil Pump

Oil Fluid Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

25 Oil Pumps found

| Page 1 of 2 |Next >

1-20 of 25 Results

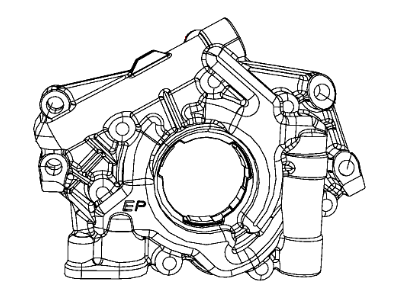

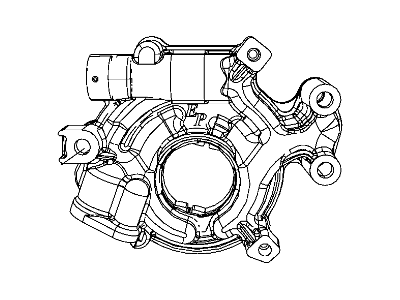

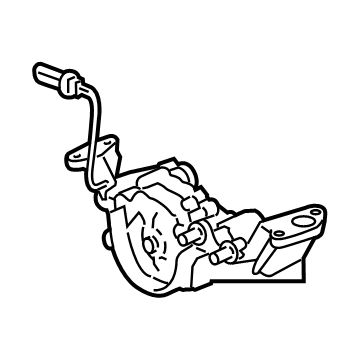

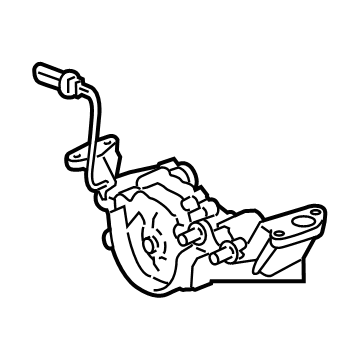

Dodge Durango Oil Pump

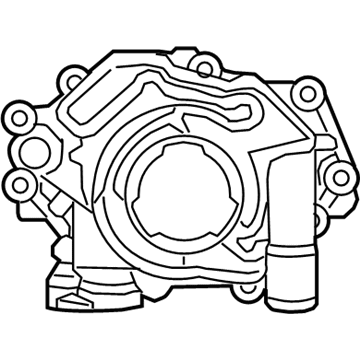

This paper aims at discussing the responsibilities of the Oil Pump in Dodge Durango vehicles particularly the internal combustion engine. It pumps the oil under pressure to help lubricate and cool vital parts of the engine that includes the bearings and pistons besides serving the role of hydraulic fluid for small actuators. The typical oil pump system that the Dodge Durango incorporates in its system is mechanical oil pumps that are driven by the crankshaft or the camshaft which are very reliable. It is worth to mention gear, trochoid and vane oil pumps which may be used in different models of the Dodge Durango. The oiling system pump sucks the oil in from the sump, filters it and then circulates it through the engine as it maintains the needed oil pressure necessary for the engine. The finesse of the Dodge Durango's power train mandated the periodic change of oil and filter and to dislodge the system clogs for the engine to savor its deserving longevity.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Durango Oil Pump at great affordable prices. Moreover, all genuine Dodge Durango Oil Pump come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Durango Oil Pump Parts Questions & Experts Answers

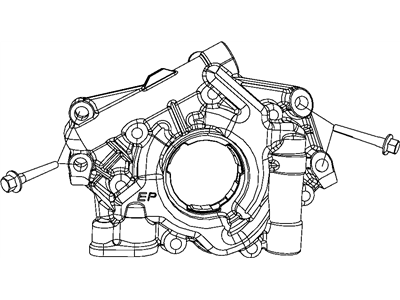

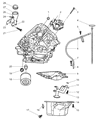

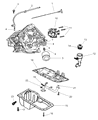

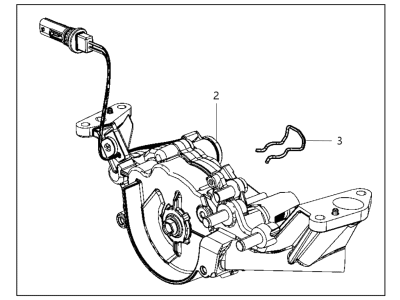

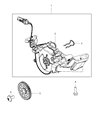

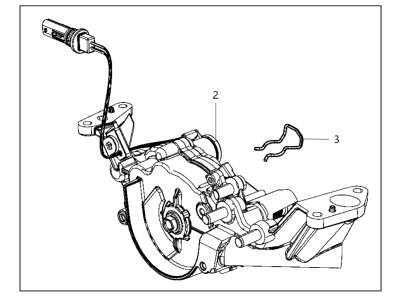

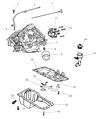

- Q: How do you remove and install Oil Pump in 3.7L V6 and 4.7L V8 engine on Dodge Durango?A:The Timing Chains and sprockets are accessed by first setting the motor back, then dropping the oil pan, windage tray and pick-up tube. Subsequently, take out bolts between the primary timing chain tensioner and oil pump, as well as the tensioner itself. Following this, remove the remaining oil pump bolts and then applying a little amount of pressure to the oil pump housing in order to locate the flats of the crankshaft while removing the pump from the engine. To check, firstly remove the cover of the oil pump by unscrewing it and removing it: lift it, then thoroughly clean all the details with solvent and assess the degree of wearing and the presence of damages. Take care here because the oil pressure relief valve and its spring are internally located in the oil pump housing and if removed they will render the pump useless requiring a complete set of pump assembly to be fitted. Check flats of pump cover using a straightedge and a feeler gauge, outer rotor and thickness, thickness of the inner rotor, outer rotor to the body space, the inner rotor to the outer rotor tip, and side clearance. As for any too large measurements, it is recommended to replace the entire oil pump assembly. To prime the oil pump tightly fill the rotor cavities with petroleum jelly and finally tighten all fasteners to manufacture torques. For installation, turn the rotor flats with the crankshaft flats and then snap the oil pump into place against the block. Last, position the primary timing chain tensioner over the oil pump, screw the pump to block bolts then tighten the Oil pump and primary timing chain tensioner bolts to the factory recommended torque in the reverse manner to which it was removed.

Related Dodge Durango Parts

Browse by Year

2025 Oil Pump 2024 Oil Pump 2023 Oil Pump 2022 Oil Pump 2021 Oil Pump 2020 Oil Pump 2019 Oil Pump 2018 Oil Pump 2017 Oil Pump 2016 Oil Pump 2015 Oil Pump 2014 Oil Pump 2013 Oil Pump 2012 Oil Pump 2011 Oil Pump 2009 Oil Pump 2008 Oil Pump 2007 Oil Pump 2006 Oil Pump 2005 Oil Pump 2004 Oil Pump 2003 Oil Pump 2002 Oil Pump 2001 Oil Pump 2000 Oil Pump 1999 Oil Pump 1998 Oil Pump