My Garage

My Account

Cart

Genuine Dodge Ramcharger Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

13 Drive Belts found

Dodge Ramcharger Drive Belt

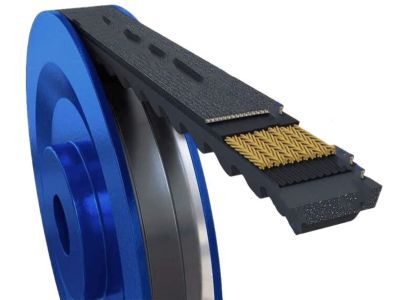

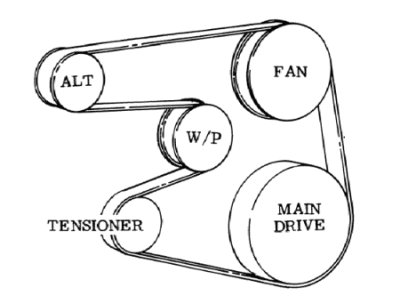

The Drive Belt used in Dodge Ramcharger automobiles ensures that several parts in the car are linked to the engine including the alternator and the Air conditioning compressor. Usually, a serpentine belt system is used, this belt goes around these parts and connects them to the crankshaft pulley assembly. Regarding the design of this gadget, its topology ensures adequate power transfer so as to enable the parts to function properly. Dodge Ramcharger models that have been produced over the years have used many types of Drive Belts such as V-belts and multi-groove belts. V-belts have greater coefficient of friction and longer service life while multi-groove belts are more flexible and accommodate the conversion of power paths. The drive belts must not be overlooked as they typically should be replaced every 100000 miles but if appears worn then must be replaced as soon as possible. Some of the problems associated with a failing Drive Belt include the following, High level of stress is placed on the parts as well as the engine in Dodge Ramcharger vehicles.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Ramcharger Drive Belt at great affordable prices. Moreover, all genuine Dodge Ramcharger Drive Belt come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Ramcharger Drive Belt Parts Questions & Experts Answers

- Q: What are the functions and maintenance requirements of drivebelts on Dodge Ramcharger?A:Located at the front part of the engine, it is known as drivebelts or V-belts, and are instrumental to the vehicle and its working parts. These belts because of their operation and construction material are known to wear out over some time and should regularly be checked and adjusted so as not to cause major damages to the engine. The number of belts depends on the accessories that are installed; they are used to attach the power generator/alternator, smog pump, power steering pump, water pump, fan, or air conditioning compressor where one belt can serve many parts due to the type of pulley design adopted. Throw the hood switch off and open the hood to check the belts for crack, worn or separated or glazed or frayed, using hands touching the belts and moving round to look at the other side, twist the belts. Looseness of the belt is determined by pressing down on the belt midway between two pulleys; by reference, a belt length of 7 to 11 inches should deflect 3/4 inch and that of 12 to 16 inches should deflect 1/2inch. To change the belt tension it is necessary to shift the belt-driven accessory on its bracket, in doing so one has to unlock the adjustment or strap bolt and the pivot bolt. after loosening, the component can be pulled away from the engine to tighten the belt or towards the engine to loosen it with breaker bar sometimes offering extra torque. After positioning of the accessory and correct belt tension, the nuts and bolts should be tightened in a little force and finally when the tension is rechecked. Sometimes the accessory may need to be shifted slightly and for this a pry bar may be needed but great care ought to be taken not to damage the component or the surface it is applied on.