My Garage

My Account

Cart

Genuine Dodge Ramcharger Piston Ring Set

Piston Ring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Piston Ring Sets found

Dodge Ramcharger Piston Ring Set

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Ramcharger Piston Ring Set at great affordable prices. Moreover, all genuine Dodge Ramcharger Piston Ring Set come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Ramcharger Piston Ring Set Parts Questions & Experts Answers

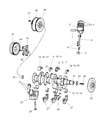

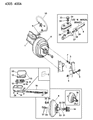

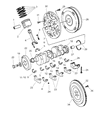

- Q: How should you check and install piston ring end gaps before engine assembly on Dodge Ramcharger?A:Before installing the new piston rings, check the ring end gaps. Lay out the piston/connecting rod assemblies and the new ring sets to match the rings with the same piston and cylinder during the end gap measurement and engine assembly. Insert the top ring into the first cylinder and square it up with the cylinder walls using the piston, ensuring the ring is at the bottom of the cylinder just below the lower limit of the ring travel. To measure the end gap, slip a feeler gauge between the ends of the ring and compare the measurement to the specifications. If the gap is larger or smaller than specified, double-check to ensure the correct rings are being used. If the gap is too small, it must be enlarged to prevent the ring ends from contacting each other during engine operation, which can cause serious damage. Increase the end gap by carefully filing the ring ends with a fine file, ensuring to file only from the outside in. Excess end gap is not critical unless it exceeds 0.040-inch. Repeat the procedure for each ring in the first cylinder and for each ring in the remaining cylinders, keeping rings, pistons, and cylinders matched. Once the ring end gaps have been checked and corrected, install the rings on the pistons, starting with the oil control ring, which consists of three components. Slip the spacer expander into the groove, then install the upper side rail without using a piston ring tool to avoid damage. Place one end of the side rail into the groove and slide a finger around the piston while pushing the rail into the groove, then install the lower side rail in the same manner. After installing the three oil ring components, ensure both the upper and lower side rails can turn smoothly in the ring groove. Next, install the middle ring using a piston ring installation tool, ensuring the mark faces up, and do not expand the ring more than necessary. Finally, install the top ring in the same manner and repeat the procedure for the remaining pistons and rings.