My Garage

My Account

Cart

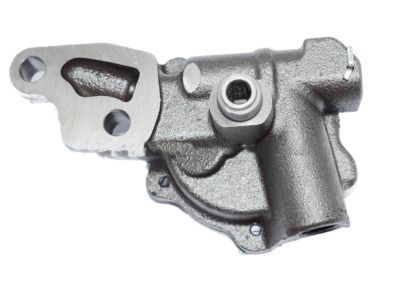

Genuine Dodge Ramcharger Oil Pump

Oil Fluid Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Oil Pumps found

Dodge Ramcharger Oil Pump

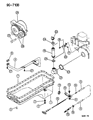

Oil Pump used in Dodge Ramcharger cars involves circulation of oil under pressure for the proper working of the internal combustion engine. This continually circulates and helps to both lubricate and cool parts such as bearings and pistons and acts as hydraulic system working fluid for tiny actuators. Mechanical oil pumps, typically Dodge Ramcharger has mechanical oil pumps with crank or camshaft driven, these are known to be very reliable. That is why, possibly, gear, trochoid and vane pumps for oil can be mounted on various models of Dodge Ramcharger produced during many years. These pumps main purpose is to pump the Oil from the sump, passes it through the filter then to circulate it throughout the engine as it preserves the right oil pressure that is so vital in the engines operation. The proper caring of the Dodge Ramcharger's engine is necessary to avoid clogging of systems and to maintain the optimum performance of the vehicle's engine in the long run one must have the oil and filter changed regularly.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Ramcharger Oil Pump at great affordable prices. Moreover, all genuine Dodge Ramcharger Oil Pump come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Ramcharger Oil Pump Parts Questions & Experts Answers

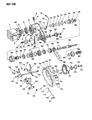

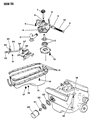

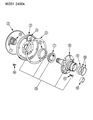

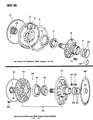

- Q: How do you properly disassemble, inspect, and reassemble an oil pump in six cylinder engine on Dodge Ramcharger?A:Remove the pump cover and sealing rings if not already done, then use a puller to take out the drive gear. Next, remove the rotor and shaft, lifting out the outer rotor. Unscrew and take out the oil pressure relief valve plug, along with the spring and plunger. Clean all parts thoroughly with solvent and check the mating surface of the pump cover for wear, grooves, and damage; if any issues are found, replace the oil pump with a new or rebuilt one. Use a straightedge and feeler gauge to check surface variation across the pump cover, comparing the measurement to the specifications; if it does not meet the required range, replace the oil pump. Measure the thickness and diameter of the outer rotor and the thickness of the inner rotor, comparing these results to the specifications and replacing the inner rotor if necessary. Install the outer rotor into the pump body, pressing it to one side, and measure the clearance between the rotor and the pump body, replacing the pump if the measurement exceeds the specified maximum clearance. Next, install the inner rotor and shaft into the pump body, checking the clearance between the inner and outer rotors; if specifications are not met, replace the shaft and both rotors. Measure the clearance between the pump face and rotors using a straightedge and feeler gauge, ensuring the straightedge lies across the pump face between the bolt holes; replace the pump if specifications are not met. Finally, measure the free length of the relief valve spring and compare it to the specifications, replacing the spring if necessary. Reassembly follows the reverse of disassembly, ensuring all parts are generously lubricated with engine oil and tightening the cover bolts to the specified torque.