My Garage

My Account

Cart

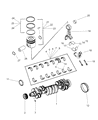

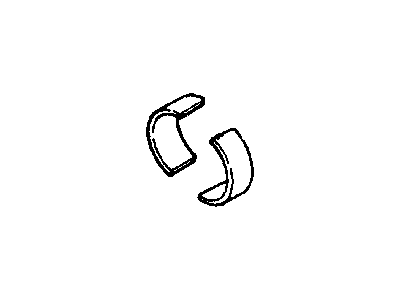

Genuine Dodge Ramcharger Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Rod Bearings found

Dodge Ramcharger Bearing Pkg-Connecting Rod

Part Number: 2421305$17.51 MSRP: $22.29You Save: $4.78 (22%)Dodge Ramcharger Connecting Rod Bearing

Part Number: 4429172$86.27 MSRP: $153.00You Save: $66.73 (44%)Dodge Ramcharger Connecting Rod Bearing

Part Number: 4429171$210.38 MSRP: $315.00You Save: $104.62 (34%)Dodge Ramcharger Connecting Rod Bearing

Part Number: 4429175$39.67 MSRP: $57.00You Save: $17.33 (31%)Dodge Ramcharger Connecting Rod Bearing

Part Number: 4429173$365.20 MSRP: $557.00You Save: $191.80 (35%)Dodge Ramcharger Bearing Pkg-Connecting Rod

Part Number: 2421309$4.18 MSRP: $5.32You Save: $1.14 (22%)Dodge Ramcharger Bearing Pkg-Connecting Rod

Part Number: 4397659$18.41 MSRP: $20.55You Save: $2.14 (11%)

Dodge Ramcharger Rod Bearing

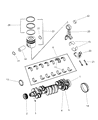

The Rod Bearing is an important component in Dodge Ramcharger vehicles as it bears the crankshaft & the connecting rods and helps the crankshaft to rotate smoothly so as to provide the required oil clearance. These bearings are generally plain bearings and these are usually bi-metal or tri-metal construction. Self-aligning bearings involve the use of an aluminum alloy lining accompanied by silicone reinforcement for increased hardness while the tri-metal offer a copper alloy as well as lead-tin-copper layer which gives extra strength and resistances the wear. In the years, Dodge Ramcharger has undergone different types of the Rod Bearings, where the sports performance often uses tri-metal type due to their superior performance and strongability to cope up with the power tunes. It also should be noted that these performance Rod Bearings can be coated with certain special substances, as well as be made with a particular off center for better lubrication and less friction to the engine. Rod Bearing play significant roles in the dynamics of the Dodge Ramcharger and thus should be properly installed as well as maintained for enhanced performance.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Ramcharger Rod Bearing at great affordable prices. Moreover, all genuine Dodge Ramcharger Rod Bearing come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Ramcharger Rod Bearing Parts Questions & Experts Answers

- Q: What are the essential steps and considerations during an engine overhaul regarding bearing replacement and inspection on Dodge Ramcharger?A:On an engine overhaul it is appropriate for the main and connecting rod bearings to be replaced by new ones but the old bearings must be retained as they can greatly indicate the state of the engine. The main causes of bearing failure include the following and should be corrected before the next assembly: Lack of adequate lubrication, the presence of dirt or counter parts, overloading of the engine, and corrosion. During the inspection of bearings they are to be taken out from the components of the engine and arranged in positions in which they were originally fit on a clean surface to match the failure with the corresponding crankshaft journal. Foreign particles can for instance contaminate the assembly equipment or filters, or be intruding through machining residues, and penetrate into the bearing during its manufacture, or during assembly, or during use at a later time; particles of this size are imbedded in the soft bearing material, and larger ones produce scoring or gouging. To avoid such a failure, the cleaning of all assemblies and constant replacement of oil and filters is required. This is through a process of overheating, overloading, oil leakage or blocked oil ways and results in a case of bearing material being rubbed off fully from its backing. It is also noteworthy that driving behaviour affects bearing life; for example, full power at low speed results in high loads that extrude oil film and cool start-and-stop cycles may promote corrosion. Further, mismounting of bearings leads to the problem of oil starvation, or high spots which leads to failure.