My Garage

My Account

Cart

Genuine Dodge Challenger Timing Belt

Engine Timing Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Timing Belt found

Dodge Challenger Timing Belt

Timing Belt can be found in Dodge Challenger automobiles and it is responsible for maintaining a correct operation of the engine crankshaft and the camshaft, while controlling the intervals of the intake as well as the exhaust valves. This act of synchronization is very important since it puts the engine in a position whereby it is capable of giving account of every stroke of the engine. The timing belt is usually produced from rubber with fiber reinforcement and is built to offer tension resistance but has a relatively small life cycle that makes it vulnerable to failure which when happens means costly damage to the engine. Dodge Challenger models have more often than not incorporated timing belts in their models while others may include timing chains or gears, especially in older models of engines. New improvements have been made on the Timing Belts whereby they have been designed with curved teeth that enable them to last longer and are also a bit quieter. Sustaining this engine entails that general upkeep is practiced in addition to observing the appropriate time for replacements of different parts.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Challenger Timing Belt at great affordable prices. Moreover, all genuine Dodge Challenger Timing Belt come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Challenger Timing Belt Parts Questions & Experts Answers

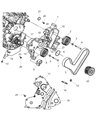

- Q: What precautions should be taken when replacing the timing belt on Dodge Challenger?A:Because this is an "interference" engine design, if the timing belt has broken there will be damage to the valves (and possibly the pistons) and will require removal of the Cylinder Heads. It is recommended that the water pump be replaced at the same time as the belt due to the work necessary to access the timing belt and the fact that the water pump is driven by it. The factory recommends replacing the timing belt at 100,000 miles. Begin by disconnecting the cable from the negative terminal of the battery. Remove the cooling fan assembly and the accessory drivebelt. Next, remove the valve covers and loosen the rocker arm shaft bolts. Raise the vehicle and support it securely on jackstands, then remove the crankshaft pulley and the drivebelt tensioner. Remove the power steering pump mounting bolts and position the power steering pump off to the side without disconnecting the fluid lines. Take off the lower and upper timing belt covers from the cylinder heads, marking the direction of rotation on the belt with white paint if it is to be reinstalled. Temporarily install the crankshaft pulley bolt and turn the crankshaft to align the timing marks on the crankshaft and camshaft sprockets, ensuring the crankshaft sprocket arrow lines up with the TDC indicator on the oil pump cover and the camshaft sprocket marks align with the marks on the rear covers. Unbolt the timing belt tensioner and remove the belt. Slowly compress the timing belt tensioner in a vise until a drill bit or Allen wrench can be inserted through the hole to lock it in place, allowing a total bleed down time of approximately four to five minutes without forcing it. With all timing marks still aligned, install the new belt at the crankshaft pulley, proceeding counterclockwise to the left camshaft sprocket, keeping tension on the belt as it is fed under the water pump pulley, over the right camshaft sprocket, and past the tensioner. If reusing the old timing belt, ensure the directional mark is pointing correctly. Hold the tensioner pulley against the belt and install the tensioner, tightening the tensioner bolts to the specified torque. Remove the Allen key or drill bit from the tensioner to allow it to tension the pulley on the belt, then tighten the rocker arm shaft bolts in the proper sequence to the specified torque. Rotate the crankshaft pulley through two complete revolutions to check that the timing marks remain aligned; if not, repeat the belt installation process. The remainder of the installation follows the reverse order of removal. Start the engine and check for leaks, noting that noise may be present upon initial startup due to air entering the timing chain tensioner; if this occurs, raise the idle to 1,600 - 2,000 rpm for ten minutes to purge the air from the tensioner, with the noise lasting no longer than 15 minutes after initial startup.